Governor McAuliffe Announces 83 New Jobs in Giles County

GLEN LYN, VA – Governor Terry McAuliffe today announced that Interstate Group LLC, an industry leader in the manufacturing and sale of enclosed cargo trailers, will invest $4.1 million to establish a 100,000-square-foot East Coast manufacturing and distribution operation in the former GE Fairchild Mining Equipment plant in Giles County. Virginia successfully competed against North Carolina for the project, which will create 83 new jobs.

“We are thrilled that Interstate Group has selected Giles County and the Commonwealth as the home of its East Coast operations,” said Governor McAuliffe, speaking at the announcement. “This important project will not only create new jobs for an area that has been hard hit by recent closures, it will bring a shuttered plant back into productive use. With one of the nation’s largest transportation networks, an outstanding workforce, and competitive operating costs, the Commonwealth is the ideal location for Interstate Group as it expands its footprint. This is a major win for the New River Valley, and we are proud the company will contribute to our efforts to diversify and build a new Virginia economy.”

Founded in 1995, Interstate Group LLC is an industry leader in the manufacturing and sales of enclosed cargo trailers. The company is headquartered in Nampa, Idaho, and has manufacturing plants in Arkansas, Arizona, and Idaho.

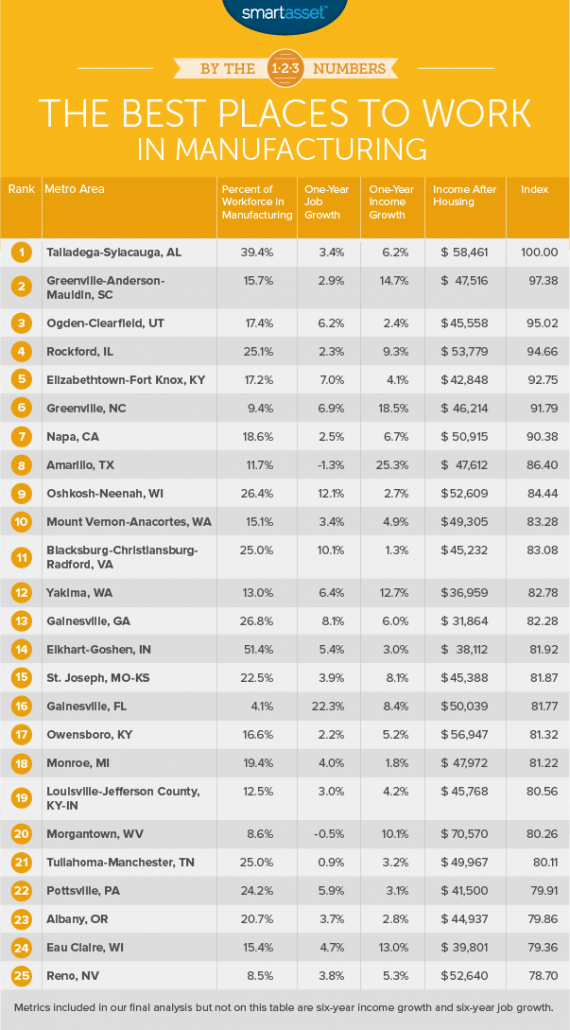

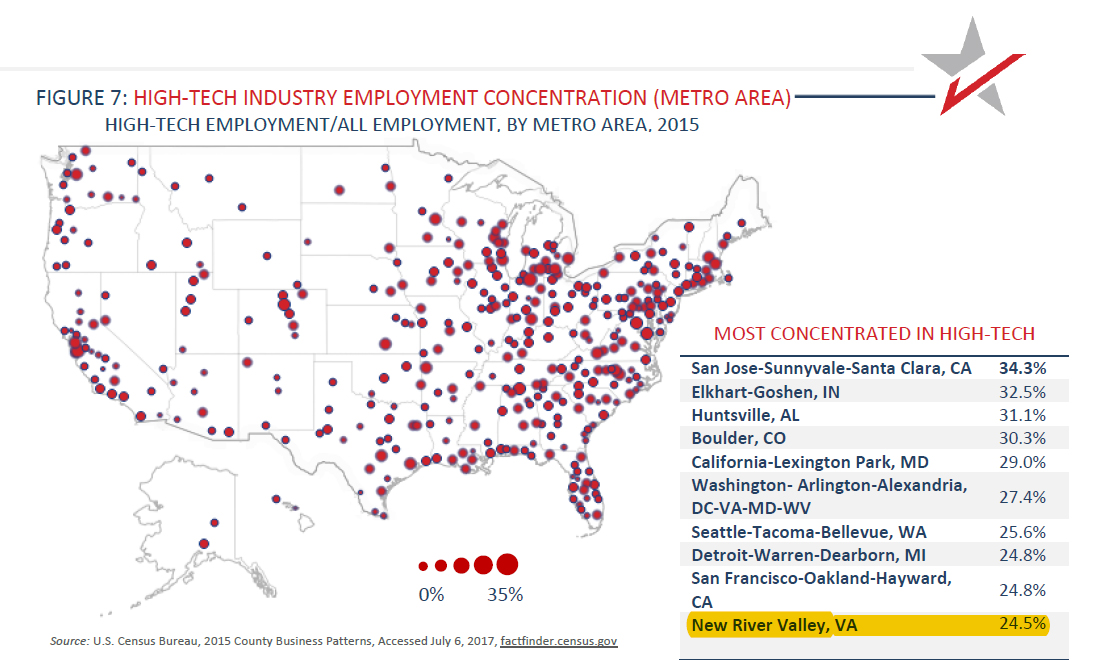

“Strengthening the advanced manufacturing sector in the Commonwealth continues to be a top priority, and Interstate Group will be a great addition to the growing cluster in the New River Valley,” said Secretary of Commerce and Trade Todd Haymore. “Interstate Group joins nearly 6,000 manufacturing firms that operate in Virginia and generate more than $113 billion in direct annual economic output, and will bring vital, quality jobs to the region. We’re proud to add the company to our corporate roster, and we look forward to a long partnership.”

“Interstate is excited to select Glen Lyn as the location for our fourth and largest manufacturing plant,” said Michael Snow, CEO of Interstate Group. “We looked at other states in the region and at multiple locations in Virginia. The opportunity to repurpose an existing facility, combined with the incentives we received from the Commonwealth and Giles County, will help us reduce the cost of our investment while preserving our culture of high incentive-based pay for our team members. I have been very impressed with the understanding and responsiveness of the state and local officials to our needs and timelines. We look forward to being part of this community and making it the foundation of our growth on the East Coast.”

The Virginia Economic Development Partnership worked with Giles County and Onward New River Valley to secure the project for Virginia. Governor McAuliffe approved a $200,000 Commonwealth’s Opportunity Fund to assist the County with the project. The company will be eligible to receive Sales and Use Tax Exemptions on manufacturing equipment, and will also be eligible to receive a Major Business Facility Job Tax Credit. Funding and services to support Interstate Group’s employee training activities will be provided through the Virginia Jobs Investment Program.

“This is great news for the entire New River Valley and we are very excited that Interstate Group has chosen Giles County as the location for its East Coast manufacturing facility,” said Richard McCoy, Chairman of the Giles County Board of Supervisors.

“These jobs are much needed in an economy that has been hard hit by downturns in the coal industry” added Dr. S. Lee Wheeler, Chairman of the Giles County Industrial Development Authority. We appreciate the work of the Economic Development Partnership, the Governor’s office, Onward New River Valley, and all of all those involved in making this a reality.”

Office of the Governor

Contact: Brian Coy

Email: Brian.Coy@governor.virginia.gov

Virginia Economic Development Partnership

Contact: Suzanne Clark

Phone: (804) 545-5806

Email: sclark@yesvirginia.org

Interstate Group LLC

Contact: Michael Snow

Phone: 208 442 7640

Email: snowm@interstatecargo.com

Virginia’s New River Valley: For those searching for an inspiring place to live and do business, Virginia’s New River Valley provides both an eclectic small town atmosphere and an innovative, collaborative business community with a loyal, highly skilled, and educated workforce. Offering the best of both worlds – magnificent mountains, cutting-edge research, arts, entertainment, and education – it’s A NATURAL FIT.

Onward NRV: Onward NRV is a public/private, regional economic development organization whose mission is to attract and retain world class jobs, investment and talent in Virginia’s New River Valley. It’s also a movement where leaders from business, government, and higher education work together to promote the economic vitality of the region.